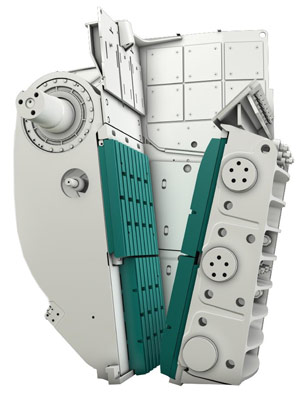

one of the most important types of crushers which is often used as the primary crusher in mines.

Although the jaw size is specified by the dimensions of the top rectangular opening, jaw length is also very important determining the performance and production capacity of the crusher.

The jaw components, namely: nut screws, ball screws, jaw fitting screws and cane bolts are all manufactured from hardened steel, which extends the durability of parts in heavy duty applications.

The main shaft of jaw crushers is manufactured from MO40 Steel and the skirtings are made of abrasion-resistant steel.

The location of framework bearings is bored using a fixed boring machine which elongates the life of roller bearings and provides a smooth performance without noise or vibration.

Moreover, all toggles used in jaw crushers are manufactured by casting (not forging) carbon steel.

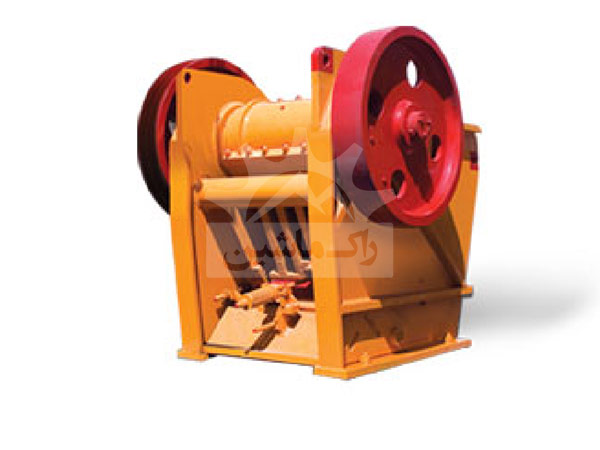

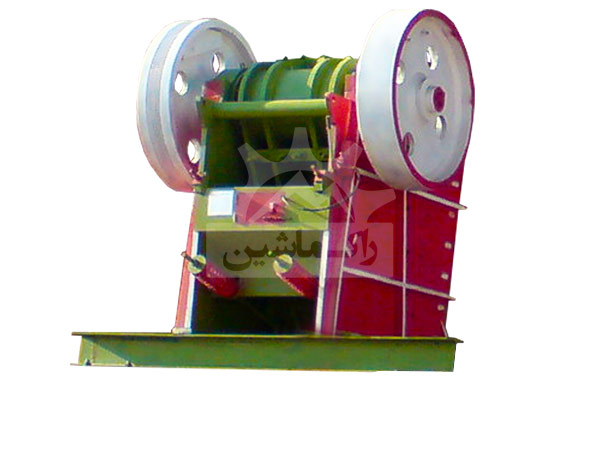

Our jaw crushers are single toggle jaw crushers designed to crush a variety of stones. Using high-quality materials we construct crushers up to a jaw width of 1200 x 1000 mm. mature designs and careful execution helped lay the excellent reputation of our crushers both at home and abroad.

Features Include:

- High crushing power and capacity

- Abrasion resistant Manganese Steel parts

- Robust, resistant structure

- Uniform output

- Elegant design and reliable performance

- Fast and easy part replacement

- Durable jaws

- Less erosion and higher resistance compared to similar crushers

- High efficiency and low maintenance costs thanks to the lubrication system